Zon Rotary Kiln Zones

مجال التطبيق

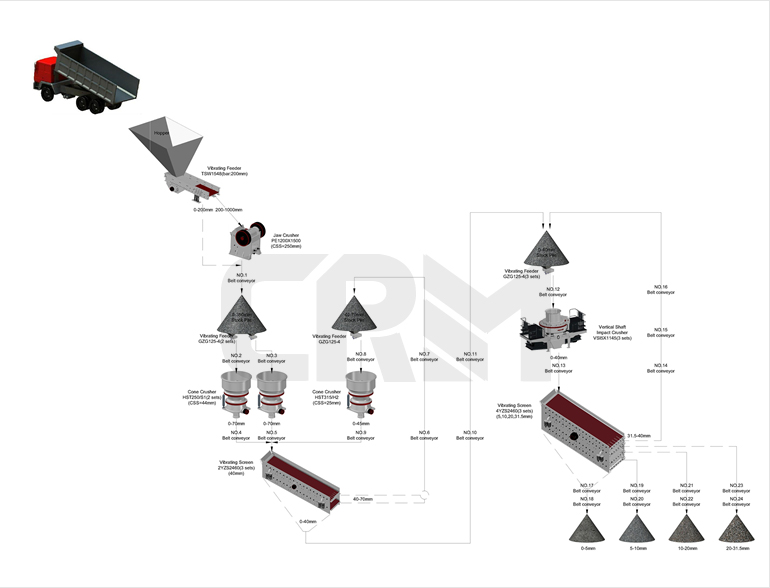

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

Chapter 10: Rotary Kiln - Clinkerization and Thermal

2022年7月2日 Depending on the temperature range, there are different thermal zones inside the kiln (preheaters and rotary kiln). What are the thermal zones and transformation of the cement kiln? We...

Rotary kiln: (a) elevation view showing the different

Rotary kiln: (a) elevation view showing the different zones in which the kiln is divided: zone 1 (admission), zone 2 (subdivision of the material), zone 3 (calcining). (b) ground plan of the...

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction. This widespread

Kiln zones and refractory materials. Download

Context 1. ... dry process, the raw ingredients are prepared and stored without addition of water, and the kiln is commonly divided into five zones (Table 2 and Fig. 3). The refractory brick...

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 Multizone heat distribution in the rotary kiln unit is investigated by employing CFD, an analytical algorithm and measurement tools in different zones of the

The schematic diagram of the cement rotary kiln

The schematic diagram of the cement rotary kiln thermal zones: (A) -Decomposition; (B) -Transition; (C) -Sintering. 1 -Feed In; 2 -Drive gear; 3 -Firebrick lining and steel shell; 4 -Tyre; 5...

Rotary Kiln - SpringerLink

2022年11月16日 Rotary kiln is the thermal equipment for high-temperature heat treatment of solid raw materials in a rotary cylindrical kiln, also called rotary furnace, which is a

Mathematical modelling of rotary cement kilns by the zone method

A steady state mathematical model of rotary cement kilns based on the fundamental principles of the physical and chemical processes within the kiln was developed. The

SVM predictive control for calcination zone temperature in lime

2017年9月18日 To improve the control performance of calcination zone temperature in a lime rotary kiln, a predictive control method based on a support vector machine (SVM)

View updated Rotary International zone structure

2023年7月12日 — In addition, the Board conducts a comprehensive review at least every eight years to comply with RI Bylaws that districts and clubs be divided into 34 zones of approximately equal number of Rotarians. Download the latest zone list and zone maps. Contact cds@rotary with questions.

Flame image recognition system for alumina rotary kiln burning zone

In the rotary kiln alumina production process, because of the complexity and variability of rotary kiln burning zone conditions, some important quality index related process parameters can not be detected continuously on-line.Detecting the different burning zone conditions on-line is a key factor for the whole process automation of alumina industry.

Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

2006年9月6日 — In cement kiln a lot of reaction are takes place at different temperatures' in the different zones of the kiln. As described in [6] by referring (Wang et al., 2006), When the kiln feed enters the ...

Rotary Kiln - an overview ScienceDirect Topics

The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction. This widespread application can be attributed to factors such as the ability to handle varied loads, with large variations in particle size [1].The rotary kiln is a slightly inclined steel cylinder that rests on supports (bearing

Research on Given Algorithm of Temperature Setting Value of Cement ...

In the cement rotary kiln firing system, the firing zone temperature is an important monitoring indicator reflecting the firing condition of the clinker in the kiln. The value of the firing zone temperature also indirectly reflects the heat consumption during the calcination process and the quality of the cement clinker. How to determine the setting temperature

Main zones, chemical reactions, and energy use in a shaft kiln

Download scientific diagram Main zones, chemical reactions, and energy use in a shaft kiln [21, 22] Figure 4. Zones and temperature profiles in the shaft kiln from publication: Energy ...

Mathematical modelling of rotary cement kilns by the zone method

The zone method of analysis was utilized together with the Monte Carlo method to simulate the radiative interchange within the kiln. Steady state energy balances including the chemical reaction terms for each zone were solved simultaneously to give temperature distributions in gas and solid charge, and composition distribution in solid charge.

Schematic diagram of the calcining process in a carbon rotary kiln ...

In the calcining process, the kiln is usually divided into three zones, i.e., preheating zone, calcining zone and cooling zone, as shown in Fig. 1. The preheating zone is at the beginning of the ...

Mathematical modelling of rotary cement kilns by the zone

Mathentatical model developed Application of t h e Zone Method t o Rotary Cement Kilns I n a rotary cement kiln one can identify f o u r types of zones: ( 1 ) gas zones of volume V ; ( 2) solid charge zones of surface area A,,, exposed t o combustion gases; (3) kiln inside surface zones of area A , ; and ( 4 ) kiln outside surface zones of area ...

What is the temperature zone in a rotary kiln?

The temperature zone in a rotary kiln is controlled and varies according to the specific process requirements, typically ranging from 800 to 2,200°F (427 to 1204°C). The kiln is designed to maintain different temperature profiles along its length to facilitate various stages of material processing.

Mathematical modelling of rotary cement kilns by

Mathentatical model developed Application of t h e Zone Method t o Rotary Cement Kilns I n a rotary cement kiln one can identify f o u r types of zones: ( 1 ) gas zones of volume V ; ( 2) solid charge zones of surface

Mathematical modelling of rotary cement kilns by the zone method

The zone method of analysis was utilized together with the Monte Carlo method to simulate the radiative interchange within the kiln. Steady state energy balances including the chemical reaction terms for each zone were solved simultaneously to give temperature distributions in gas and solid charge, and composition distribution in solid charge.

3 Common Problems Seen in Lime Kilns Kiln Technology

2021年8月23日 — 2. Shifting calcination zones. The ideal area for calcination to occur is in the center of your rotary kiln. If the heat zone shifts too far up or down the kiln, it could significantly affect output. The main reason this could happen is improper airflow. If the calcination zone is shifting upwards, too much air is being used.

Coating and Burnability of Clinker SpringerLink

2019年8月27日 — Coating plays a very important role on the refractory life in burning zone, of the rotary kiln, where the condition is most arduous. The mechanism of coating formation and the stability of coating largely determine the refractory life. The factors those help...

Main zones, chemical reactions, and energy use in a shaft kiln

Download scientific diagram Main zones, chemical reactions, and energy use in a shaft kiln [21, 22] Figure 4. Zones and temperature profiles in the shaft kiln from publication: Energy ...

Fuzzy control of rotary cement kiln using sintering zone image ...

Article analyses modern machine vision-based approaches of the rotary kiln monitoring and control which reduces energy consumption and improve clinker quality. Article describes fuzzy advising control unit developed by the authors. It based on sintering zone state assessment, the kiln rotation period and the relative change of the exhaust gases

Basic Rotary Kiln different Heating zone of Pyroprocessing

2021年8月4日 — Lecture-5 : Basic Rotary Kiln different Heating zone of Pyroprocessing system by Dr K Mohan.Dr K Mohan is an internationally renowned and an acclaimed ceme...

What is the temperature zone in a rotary kiln?

The temperature zone in a rotary kiln is controlled and varies according to the specific process requirements, typically ranging from 800 to 2,200°F (427 to 1204°C). The kiln is designed to maintain different temperature profiles along its length to facilitate various stages of material processing.

Cement kiln - Wikipedia

Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln. [2] [3] [4] The basic, egg-cup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught and thus obtain the higher temperature needed to make cement clinker.For nearly half a century, this design, and minor

سابق: نيجيريا الحجر

التالي: قائمة أسعار آلة طاحونة باجاج

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت